What is DTF Printing? A Complete 2025 Guide to Direct to Film Technology

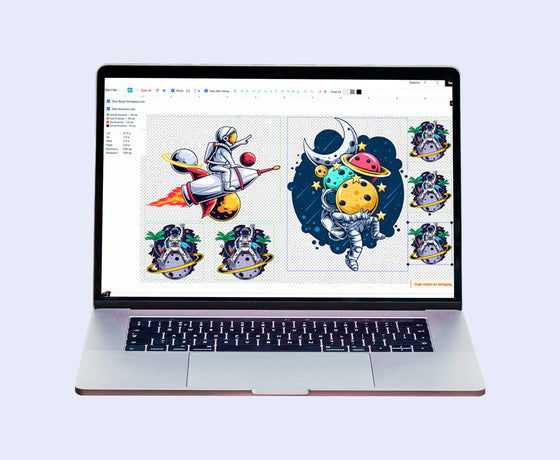

In the fast-evolving world of textile customization, DTF printing—short for Direct to Film printing—has emerged as a cutting-edge solution for businesses and hobbyists alike. Whether you run a custom t-shirt shop, an e-commerce store, or a print-on-demand service, understanding DTF printing is essential in 2025.

But what is DTF printing, and why is it gaining so much popularity? This guide will walk you through everything you need to know about the process, technology, materials, and how to succeed in the DTF printing business.

What Does DTF Stand For?

DTF stands for Direct to Film. Unlike other methods such as Direct to Garment (DTG), the DTF process prints the design on a specialized film, which is then transferred to fabric using heat and pressure.

Key Takeaways:

-

DTF = Direct to Film

-

Uses PET film and adhesive powder

-

Requires a heat press to transfer the design to fabric

How Does DTF Printing Work?

DTF printing involves several stages. Understanding each one helps you troubleshoot problems and deliver high-quality products.

The Basic Workflow:

-

Design creation using graphic software like Adobe Illustrator or Photoshop.

-

Print design in reverse using a DTF printer on PET film.

-

Apply adhesive powder to the wet ink.

-

Cure the powder using a heat source.

-

Transfer the design to fabric using a heat press.

-

Peel the film while hot or cold, depending on the film type.

Unlike other methods, DTF allows high-detail, full-color prints on almost any fabric type, including polyester, nylon, and cotton blends.

DTF vs. DTG vs. Screen Printing

If you're evaluating print methods, it helps to compare DTF with traditional techniques.

| Feature | DTF Printing | DTG Printing | Screen Printing |

|---|---|---|---|

| Fabric Compatibility | All fabrics | Cotton only | Cotton & blends |

| Setup Time | Low | Low | High |

| Color Vibrancy | High | Medium | High |

| Durability | High | Medium | High |

| Print Cost (Low Qty) | Low | Medium | High |

| Learning Curve | Medium | Medium | High |

DTF printing stands out for versatility and ease of use, especially for small orders and full-color prints.

Benefits of DTF Printing

There are many reasons why entrepreneurs and designers are switching to Direct to Film technology.

Key Benefits:

-

Works on all fabric types (cotton, polyester, blends, nylon)

-

No pre-treatment needed like DTG

-

High-quality, vivid colors

-

Wash-resistant and durable prints

-

Low production costs, especially for small orders

-

Ideal for print-on-demand businesses and Etsy shops

Materials Required for DTF Printing

Before you start, you need to gather the essential materials. The quality of each component significantly affects the final output.

Essential Materials:

-

DTF Printer (modified inkjet printer)

-

PET Film Sheets (preferably cold peel)

-

DTF Ink (CMYK and white)

-

Hot-Melt Adhesive Powder

-

Heat Press

-

Design Software (Adobe Illustrator, Photoshop, or Canva)

Investing in quality materials ensures fewer errors and better print quality.

Best Fabrics for DTF Printing

One of the most powerful features of DTF is its fabric versatility.

Compatible Fabrics:

-

Cotton

-

Polyester

-

Nylon

-

Lycra/Spandex

-

Blended fabrics (poly-cotton)

-

Denim

-

Canvas

Whether you’re printing on a cotton hoodie or a polyester gym bag, DTF handles it effortlessly.

DTF Printing Process Step by Step

Step 1: Design Creation

Create your artwork using design software. Ensure it is in CMYK color mode and includes a white underbase layer.

Step 2: Printing

Print the design in mirror mode on PET film using a DTF printer. First print the color layer, followed by the white ink layer.

Step 3: Powder Application

Apply hot-melt powder manually or via a powder shaker machine. Ensure the powder sticks to the printed ink only.

Step 4: Curing

Melt the powder using a heat press (no pressure) or an oven at around 320°F for 2–3 minutes.

Step 5: Transfer

Place the cured film onto the fabric and heat press it at 320°F with medium pressure for 15 seconds.

Step 6: Peeling

Peel the film. Cold peel films should be allowed to cool for best results.

Step 7: Post Pressing (Optional)

Repress the fabric for a few seconds to improve washability and finish.

DTF Printer Maintenance and Care

Proper maintenance is crucial for consistent quality.

Maintenance Tips:

-

Clean print heads daily to prevent clogging

-

Shake white ink cartridges regularly

-

Perform nozzle checks before every print session

-

Use humidity control in print environment

A well-maintained printer ensures long-term savings and fewer technical issues.

DTF Printing Costs and Profit Margins

The cost-efficiency of DTF makes it attractive for small businesses.

Estimated Costs (Per Shirt):

-

Ink: $0.50

-

Film: $0.30

-

Powder: $0.20

-

Total Material Cost: ~$1.00

Selling Price: $15–$25 per shirt

Gross Profit Margin: ~90%

Low material cost and high retail value make DTF extremely profitable.

Common Problems in DTF Printing and How to Fix Them

Common Issues:

-

Ink Smudging: Caused by low-quality film or wrong drying temperature

-

Powder Not Sticking: Ink may be too dry before powdering

-

Colors Dull After Transfer: Incorrect pressing temperature/time

Always follow manufacturer recommendations for optimal settings.

Future of DTF Printing

DTF printing is more than a trend—it’s a revolution in textile printing. As printer technology advances and materials improve, expect:

-

Automated powdering and curing

-

Eco-friendly inks

-

Increased print resolution and color accuracy

The future looks vibrant for DTF enthusiasts and entrepreneurs.

Frequently Asked Questions (FAQ)

What is DTF printing?

DTF (Direct to Film) printing is a process where a design is printed onto PET film and then transferred to fabric using heat.

Is DTF better than DTG?

DTF is more versatile because it works on all fabric types and doesn’t require pre-treatment.

How long do DTF prints last?

With proper washing, DTF prints can last over 50 washes without fading or cracking.

Can I use any printer for DTF?

No. You need a modified inkjet printer compatible with DTF inks.

Is DTF printing eco-friendly?

Some newer DTF inks are water-based and eco-conscious, but it depends on the brand.

Final Thoughts and Call to Action

Whether you’re just starting out or looking to scale your apparel business, DTF printing offers unmatched flexibility, cost savings, and print quality. Unlike DTG or screen printing, you won’t be limited by fabric type or order size.

Want to learn more? Don’t wait. Contact us today and transform the way you customize apparel.

This guide was written exclusively for educational purposes and reflects the latest standards in DTF printing as of 2025.